Company Profile

Hongtai Wire Co., LTD., Yutian Xiangtai Metalwork Co.LTD., and Tangshan Fengrun District Hengwei Trading Co., LTD. have always adhered to the working concept of "pragmatism, dedication, harmony, win-win, innovation and development" and the business purpose of "quality-oriented, honest management, customer service, benefiting one party and giving back to the society". Over the years, the three enterprises have been deeply engaged in their respective fields. By continuously optimizing production processes, improving service systems and expanding market channels, they have achieved steady business growth and made remarkable development achievements. Nowadays, they have not only grown into county-level leading enterprises, but also driven the coordinated development of the local industrial chain with strong development vitality, injected sustained impetus into regional economic growth, played an important role in promoting employment and driving local industrial upgrading, and shown a vigorous and promising development trend.

Why Choose Us

Advanced Equipment

Machines, tools, or instruments designed with advanced technology and functionality to perform highly specific tasks with greater accuracy, efficiency, and reliability.

Professional Team

utian Xiangtai Metalwork Products Co., Ltd. boasts 30 years of rich production experience and is a comprehensive private enterprise integrating production and sales. The company currently has more than 800 employees, among whom over 100 are professional technicians and managers. With solid industry knowledge and extensive practical experience, this professional team provides strong support for the company's production research and development, quality control, and market expansion, helping the company develop steadily in the field of metal products.

Rich Experience

Over the years, the company has organized sales in more than 200 large and medium-sized cities with high-quality products, reliable reputation and good service.

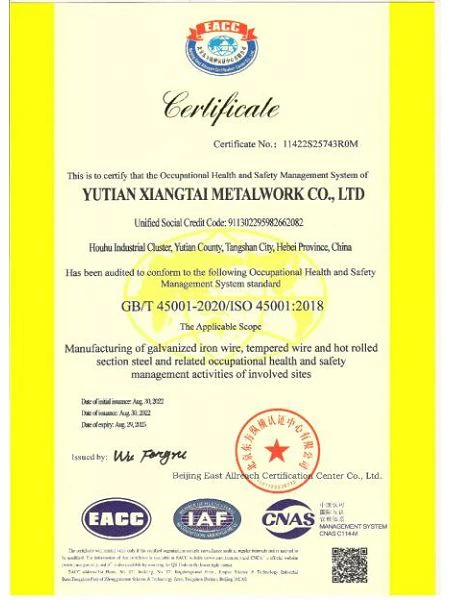

Certificate

It has established solid contacts with more than 1000 distributors, and has been exported to Europe, Africa and the Middle East, and has received unanimous praise from foreign distributors.In order to promote the local economic development, we have been committed to the quality management system, and our products have passed the IS09001 inspection and certification smoothly.

The use of iron nails

1. "10 Unique Uses for Nails Beyond Just Hanging Pictures"

2. "The Versatility of Nails: From Construction to DIY Projects"

3. "Beyond Hammering: Surprising Uses for Nails in Everyday Life"

4. "Innovative Ways to Utilize Nails in Home Decor"

5. "The Essential Tool: How Nails Serve Multiple Purposes in Construction"

6. "Nail It: Creative Ways to Incorporate Nails in Arts and Crafts"

7. "From Roofing to Crafting: The Multifaceted Role of Nails in Society"

8. "Think Outside the Toolbox: Unconventional Uses for Nails in DIY Projects"

9. "The Power of a Tiny Object: How Nails Have Revolutionized Construction and Decoration"

10. "Beyond Functionality: How Nails Can Add a Unique Aesthetic to Your Space"

Advantages of Common wood Nails

Corrosion Resistance

The most significant distinction between the two types of nails lies in their corrosion resistance. Galvanised nails, thanks to their zinc coating, are highly resistant to rust and corrosion, making them an ideal choice for outdoor projects, such as fencing, decking, and siding. Bright round wire nails, being untreated, are more prone to rust and should be used primarily for indoor applications like furniture assembly and trim work.

Durability

Galvanised nails have greater durability thanks to their protective coating. This special coating can effectively block corrosive substances such as moisture and oxygen, enabling them to show better resistance than bright round wire nails in harsh weather, drastic temperature changes and environments exposed to chemicals. In contrast, bright round wire nails, which lack a protective coating, are more suitable for light-load scenarios where extreme durability is not required, such as the assembly of indoor light furniture and the fixing of small wooden crafts that do not need to withstand harsh environmental tests for a long time.

Aesthetics

The appearance of the two nails differs significantly. Galvanised nails have a dull, matte finish due to their zinc coating, while bright round wire nails have a shiny, polished look. This difference may influence your choice depending on the visibility of the nails in the project.

Secure Hold

The larger, rounded head design of these nails provides a secure hold when suspending items. This helps prevent shifting or falling, ensuring that the hung objects remain in place.

Easy Installation

Round head hanging nails are easy to install. Their pointed tips allow for quick insertion into walls or other surfaces without the need for pre-drilling. This saves time and effort during the installation process.

Versatility

These nails are versatile and can be used for a wide range of hanging applications. Whether it's hanging picture frames, shelves, decorations, or organizing accessories, round head hanging nails provide a reliable solution

Clipped Head And Round Head Nailers a Difference Between The Two

The big difference between clipped head and round head nailers is that a clipped head nailer can hold about 20-30% more nails in the same magazine size than a round head nailer.

This is due to the way that the nails are strung together, or 'collated'. When clipped head nails are collated, the flat ends of the heads butt right up next to each other, drastically decreasing the space between two nails, and thus increasing the amount of nails you can fit into the nailing gun's magazine.

Round head nails take up more space than clipped head, because the heads do not line up flush with one another when they're collated - you have a full head's width between each nail.

Being that clipped heads can pack together more tightly, the magazine on clipped head nailers is typically shorter than those of round head nailers. This is a big perk to some users, as it allows for a little less weight and more maneuverability in tight or hard to reach spaces.

On the contrary, round head nailers have a longer, heavier magazine, which some other users feel is an advantage as it provides more balance to the gun.

Indoor Applications: Bright round wire nails are ideal for indoor projects, such as furniture assembly, cabinetry, and trim work, where exposure to moisture is minimal.

Decorative Projects: When the appearance of the nail is important, such as in crafts or decorative woodwork, the bright and shiny finish of these nails can add a pleasing aesthetic touch.

Construction: Round wire nails are versatile and suitable for various construction tasks.

Timber Framing: They are commonly used for roof rafters, floor joists, wall partitions, and stud work.

Fencing: Round wire nails are also ideal for heavy-duty fencing projects.

Grip better than Round Wire Nails for a bunch of reasons

When you drive a nail in, you push down the wood fibers. After nailing, for the nail to come out, it has to overcome the force from thousands of wood fibers that act like tiny barbs gripping the nail. Round wire nails are cylindrical and only taper at the tip, so the wood fibers along the nail's shaft are only slightly bent. In contrast, cut nails are tapered throughout their length, and as the nail goes deeper, the taper increases. This causes more and more wood to be pushed aside, resulting in a growing force that resists pullout.

However, more all-around wedging action also means a higher risk of splitting the wood. When you hammer in a wire nail, its pointed tip wedges the wood in all directions. A larger wire nail will have greater holding power than a smaller one, but it will also exert more force that can split the wood. Cut nails are tapered in only one dimension, and when installed correctly with the wedge parallel to the wood grain, the nail's taper follows the grain. This prevents it from forcing the wood to split, and the parallel sides of the nail won't create a wedging action that would cause splitting. Thus, for nails of the same size and length, cut nails provide significantly more holding power.

Why are cut nails better? The wedging action of a wire nail is fixed by the diameter of its tip. In contrast, the continuously increasing taper of a cut nail allows for much stronger wedging. Some cut nails (such as boat nails) have a wider section in the middle, so the wood around the top of the nail can swell back to wrap around it, enhancing strength even further.

The square cross-section of a cut nail resists attempts to twist the wood, which is a common issue with round wire nails. This reduced movement helps keep the nailed structure stable.

Cut nails are tapered from top to bottom, so the top piece being nailed down is held firmly by the nail's taper, eliminating the need for a large head. This allows cut nails to have a much smaller head, which can be easily set flush with the wood surface. Wire nails, with their weaker gripping force, rely heavily on the head to prevent the joint from separating, making the head more noticeable.

Additionally, while unrelated to holding power, the top of a cut nail is smooth and less likely to deflect under a hammer blow compared to the pinched top of a wire brad. This makes cut nails more reliable and easier to drive in.

Yutian Xiangtai Metalwork Co.,Ltd, established on 2012, is a compreshensive private enterprise intergrating the production and sales of metal products. Which has fixed assets of 500 million yuan and 860 employees.

Our Certificate

FAQ

Hot Tags: iron nails, galvanized round nails, specially designed for construction carpentry. made of low-carbon steel. available in sizes ranging from 2 inches to 4 inches. complete range of specifications. factory direct sales, China iron nails, galvanized round nails, specially designed for construction carpentry. made of low-carbon steel. available in sizes ranging from 2 inches to 4 inches. complete range of specifications. factory direct sales manufacturers, suppliers, factory, 12 Gauge Galvanized Wire, 16 Gauge Galvanized Wire, Electro Galvanized Wire, Galvanized Wire, Galvanized Wire Mesh, Galvanized Wire Rolls