What Is Galvanized Wire

Galvanized iron wire is designed to prevent rusting and shiny silver in color,durable and extremely versatile,it is widely used by landscapers,craft makers,building and constructions,ribbon manufacturers,jewelers and contractors.Its aversion to rust makes it extremely useful around the shipyard,in the backyard,etc.

Galvanized wire is divided into hot dipped galvanized wire and cold galvanized wire(electro galvanized wire).Galvanized wire has good toughness and flexibility,the maximum amount of zinc can reach 350g/sqm.With zinc coating thickness,corrosion resistance and other characteristics.

Galvanized wire is a type of wire that has undergone a galvanizing process to protect it from corrosion and improve its durability. This process involves coating the wire with a layer of zinc, which creates a barrier between the wire and the element.

This type of wire undergoes a specialized coating process to form a dense zinc layer, which acts as a protective barrier against moisture, oxidation, and chemical exposure. Unlike ordinary steel wire, its corrosion-resistant structure ensures prolonged durability in outdoor environments, harsh weather conditions, or industrial settings where rusting is a major concern.

Galvanized wire, a corrosion-resistant metallic product, is formed by coating steel wire with a protective zinc layer. This zinc plating not only wards off rust and oxidation but also significantly extends the wire's service life, making it a preferred choice for applications requiring long-term durability.

Galvanized wire is a type of wire that has been coated with zinc in order to protect it from rust and corrosion. Galvanized wire is highly durable and can be used for a wide range of applications, including fence building, agricultural applications, and construction projects.

Galvanized wire is a type of wire that has been coated with a layer of zinc to prevent rusting and increase durability.

Galvanized iron wire, also known as electro galvanized wire or hot-dipped galvanized wire, is a type of steel wire that has undergone a galvanization process to prevent rust and corrosion. The process involves coating the wire in a protective layer of zinc, which forms a barrier against moisture, chemicals, and other environmental factors that can cause damage to the wire.

Zinc-coated iron wire, also known as galvanized iron wire, is a popular product in the wire industry. It is used in various applications, such as construction and agriculture.

Galvanized wire is a type of wire that has been coated with a layer of zinc to prevent rusting and corrosion. This wire is widely used in various applications such as fencing, construction, agriculture, and packaging. The advantages of galvanized wire are numerous, making it a preferred choice for many industries.

Unlike ordinary steel wire, its zinc-plated structure offers dual protection: the physical barrier of the coating and the sacrificial corrosion resistance of zinc, which prioritizes its own degradation to safeguard the underlying metal. This makes galvanized wire particularly suitable for outdoor applications, such as construction fencing, agricultural netting, or marine infrastructure, where prolonged exposure to humidity, salt, or chemicals would otherwise compromise durability.

Advantages of Galvanized Wire

Galvanized wire offers a number of advantages over other types of wire, including:

Corrosion resistance

The protective layer of zinc prevents rust and corrosion, making galvanized wire ideal for outdoor use.

Durability

Galvanized wire is stronger and more durable than other types of wire, which makes it suitable for a variety of applications.

Easy to work with

Galvanized wire is easy to bend and shape, which makes it easy to work with for a variety of applications.

Cost-effective

Galvanized wire is an affordable option compared to other types of wire, which makes it a popular choice for a variety of applications.

Galvanized Wire Vs. Annealed Wire

You must consider your operation's circumstances and requirements to choose the wire that best suits your needs. Consider the critical differences between the two types of wire

Rust Resistance

For applications requiring enhanced weather damage resistance, annealed wire may not be optimal. The annealing process alters the steel's physical properties, making it more susceptible to rust when used outdoors or in wet environments.

By contrast, galvanized wire offers significantly better rust resistance than annealed wire. In settings exposed to weathering and salt-such as shipyards-galvanized steel wire outperforms annealed wire due to its protective zinc coating.

Flexibility

The annealing process imparts greater flexibility to annealed wire compared to standard steel wire. This trait enhances its versatility for applications where malleability is critical. When high flexibility is a priority, annealed wire stands as the optimal choice.

Conversely, galvanized wire exhibits sturdier properties but with reduced adaptability. Its structural rigidity makes it less suited for applications requiring extensive bending or shaping.

Durability

Owing to its resistance to water and physical damage, galvanized wire demonstrates greater durability than annealed wire in targeted environments.

The Benefits of Galvanization

Galvanizing means applying a protective zinc coating to metal to help it resist damage. Galvanized metal has a wide array of benefits, including these six boons, which will help your wires remain strong for years to come.

Prevents corrosion and rust

The primary reason why people use galvanized metal is that it offers them rust and corrosion protection. When iron reacts to oxygen during moist and wet conditions, it will create rust as a byproduct. Covering wires in a zinc coating will have a shield that prevents further rust from occurring. This is especially beneficial in outdoor environments or naturally moist areas, as metal is more susceptible to corrosion in those locations.

Protection from further damage

Corrosion isn't the only threat to wires that galvanization can prevent. galvanized wires are resistant to long-term damage such as scratching and breaks that would typically cause many problems. Because galvanized metal is considerably harder to damage, you won't need to spend money or time repairing wires that suffered from harm; they won't lose their effectiveness.

Longevity

As galvanized wires are less likely to sustain damage, they will last longer. Taking the time to put your wires through the galvanizing process will ensure they will remain safe for over 20 years or possibly 50, depending on the dampness of the location. This prolonged lifespan means you won't need to replace it for several decades, making it an excellent investment you won't need to worry about.

Short process

Galvanized metal is ready to use shortly after its bath of molten zinc. The process differs based on whether you decide to use hot-dip galvanizing or galvannealing (using the traditional hot-dip method and annealing together). Still, it does not take a very long time.

Cost-effective

Compared to other protective treatments, the price of hot-dipped galvanized wire is lower and easier to afford. The actual galvanized process has a lower price than other methods, such as making stainless steel. Not having to fix your galvanized wires will also save you money on future replacement costs.

Visual inspection

Inspecting every wire to ensure it isn't damaged can take a while, but galvanized products require less inspection time. Because of the zinc coatings' formidability, all it takes to determine whether a galvanized wire is faulty or not is by a quick eye glance, which can save valuable time for other business endeavors.

Applications of Galvanized Wire

Galvanized wire is prevalent across industries and applications. The zinc coating makes galvanized wire useful in many instances where wet conditions or fire hazards make other types of wire unusable. Here are a few of the top applications of galvanized wire.

Fencing

Galvanized wire's rust and damage resistance is excellent for all kinds of fencing. galvanized wire is also durable, holding up under high pressure. You can find galvanized wire fencing everywhere, from agriculture fencing to the hexanet fencing used in insulating buildings.

Binding

Businesses frequently use galvanized wire to bind or bale construction and recycling materials into one unit. In construction applications, this wire makes it easier for construction teams to work with the materials on the job site. Many companies use galvanized wire to bind other scrap and raw materials.

Nails and staples

Construction teams need durable materials at every stage of the building process. The strength of these wires makes them ideal for providing buildings and homes with structural support. Galvanized steel wire creates sturdy nails, springs, staples and other structural elements that can withstand heavy strain.

Consumer goods

Manufacturers have found many uses for galvanized wire in consumer goods applications. From bucket handles to hanging support for artwork and mirrors, galvanized wire offers strength.

What Are the Properties of Galvanized Wire

Rust and Corrosion Protection

The primary benefit of galvanization lies in its enhanced rust and corrosion resistance. The protective zinc coating makes galvanized wire ideal for wet and outdoor environments. As zinc is anodic, it undergoes corrosion before the underlying steel, ensuring the wire remains protected until the zinc layer is fully eroded.

Strength and Durability

Galvanization improves the wire's abrasion resistance, making it suitable for harsh conditions and exposure to the elements. Through cathodic protection, even if small sections of steel are exposed, the remaining zinc coating shields them from rust. While galvanization slightly affects tensile strength (up to 10% loss in some cases), hot-dip galvanization (our method) may even slightly increase it.

Long Lifespan

Galvanization significantly extends the wire's service life. In marine or aquatic settings, it typically lasts up to 12 years, while in moderate environments, it can remain functional for up to 150 years. This longevity has made it a preferred choice for farm fencing.

Versatility

With superior corrosion resistance, abrasion resistance, strength, and longevity, galvanized wire offers exceptional versatility. It is widely used in recycling, agriculture, construction, and telecommunications-ideal for applications requiring long-term durability.

Affordability

Thanks to its durability and lifespan, galvanized wire provides a cost-effective solution. Often more economical than stainless steel wire, it eliminates frequent maintenance and replacement costs, making it a wise long-term investment.

How Is galvanized wire Different from Regular Wire

Galvanized wire is a type of wire that has been coated with a layer of zinc. The zinc coating protects the wire from corrosion, making it more durable and long-lasting. galvanized wire is often used in outdoor applications, such as fencing and electrical wiring.

Regular wire is not coated with zinc, and is therefore more susceptible to corrosion. Regular wire is often used in indoor applications, such as electrical wiring and light fixtures.

Here are some of the key differences between galvanized wire and regular wire:

Corrosion resistance: Galvanized wire is much more resistant to corrosion than regular wire. This is because the zinc coating protects the wire from the elements.

Durability: Galvanized wire is also more durable than regular wire. This is because the zinc coating helps to prevent the wire from rusting and breaking.

Cost: Galvanized wire is typically more expensive than regular wire. However, the increased durability and corrosion resistance of galvanized wire make it a worthwhile investment for many applications.

Galvanizing Process

Surface preparation. First, the wire is cleaned to remove any surface impurities. This is important for ensuring proper adhesion of the zinc coating.

Pickling. The wire is then immersed in an acid solution to remove any remaining oxides and scale.

Fluxing. The wire is then immersed in a flux solution (zinc ammonium chloride), which helps to prevent oxidation and promotes a uniform application of the zinc coating.

Galvanizing bath. Next, the wire is dipped into a molten zinc bath at a temperature of around 450°c (850°f).

Alloy formation. While immersed in the molten zinc, a metallurgical reaction occurs between the iron in the wire and the zinc, resulting in the formation of a series of zinc-iron alloy layers. These provide excellent adhesion and corrosion resistance.

Withdrawal. The wire is then slowly withdrawn from the zinc bath, ensuring the final product has an even coating.

Quenching. The coated wire is then quenched in water or a quenching solution to cool it rapidly. This process solidifies the zinc coating and completes the galvanizing process.

This multifaceted process creates a durable and corrosion-resistant coating that protects against the elements.

1. Regular Cleaning

Use water and a neutral detergent to gently scrub or wipe the surface, removing dust, dirt, and grease.

Avoid acidic, alkaline, or abrasive cleaners to prevent damage to the zinc layer.

2. Moisture Prevention

Keep galvanized wire away from prolonged wet environments, as moisture accelerates metal oxidation.

Dry the wire immediately if exposed to rain or liquid spills.

3. Chemical Contact Avoidance

Prevent contact with strong acids, alkalis, and other corrosive chemicals.

In case of splashing, rinse thoroughly with water and consult a professional for treatment.

4. Protective Coating Application

Apply protective agents (e.g., varnish or anti-rust wax) to isolate the zinc layer from air and moisture, slowing oxidation.

5. Routine Inspection

Regularly check the surface for signs of damage, corrosion, or rust.

Repair or replace damaged sections promptly to prevent corrosion spread.

6. Insulation Maintenance (for electrical use)

If used as insulation in electrical equipment, verify the integrity of the insulation layer regularly.

Keep it dry and clean to maintain insulation effectiveness.

7. Mechanical Damage Prevention

Avoid collisions or friction with sharp objects during use, storage, and handling to preserve the zinc layer's protection.

8. Proper Storage

Store galvanized wire in a dry, ventilated area, away from moisture and chemicals.

Use plastic bags or airtight containers to shield it from air and humidity.

9. Grease Application

Apply a moderate amount of mechanical grease periodically to enhance the zinc layer's protection and reduce friction/wear.

10. Environmental Consideration

Avoid exposing the wire to high-temperature or acid-alkali corrosive environments, which can damage the zinc coating.

Our Factory

Yutian Xiangtai Metal Products Co., Ltd was established on June 15, 2012. It is a comprehensive private enterprise that integrates(集成了) the production and sales of metal products. The company is located at No. 857, Huxing West Road, Houhu Industrial Park, Yutian County Economic Development Zone, Hebei Province. It currently has fixed assets(资产) amounting to 500 million yuan and 860 employees, including 100 professionals engaged in technical and managerial work across various fields. The company has become one of the top 100 private enterprises in Hebei Province and has been awarded the High-Tech Enterprise Certification.

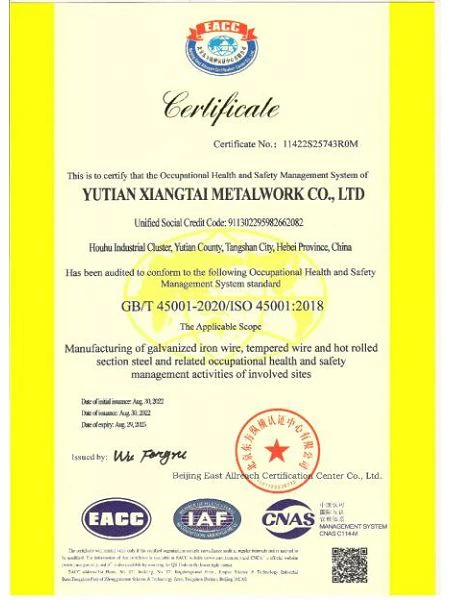

Our Certificate

FAQ

Hot Tags: q195 q235 material bwg10 bwg12 galvanized iron wire steel hot dipped carbon steel tie wire, China q195 q235 material bwg10 bwg12 galvanized iron wire steel hot dipped carbon steel tie wire manufacturers, suppliers, factory, 12 Gauge Galvanized Wire, 16 Gauge Galvanized Wire, Galvanized Wire 12, Galvanized Wire 2 mm, Galvanized Wire Rolls, Swg 12 Galvanized Wire